The Benefits of a CNC Machine Shop For Maximum Accuracy

In today's manufacturing landscape, precision and efficiency are more critical than ever. Industries from aerospace and automotive to medical devices and electronics demand parts that meet exact specifications. A CNC machine shop plays a central role in achieving this level of accuracy, combining advanced automation with meticulous control systems. By leveraging CNC technology, businesses can produce components that meet strict quality standards while maintaining productivity and reducing errors. The capabilities of a professional CNC machine shop make it an essential partner for manufacturers seeking both reliability and performance.

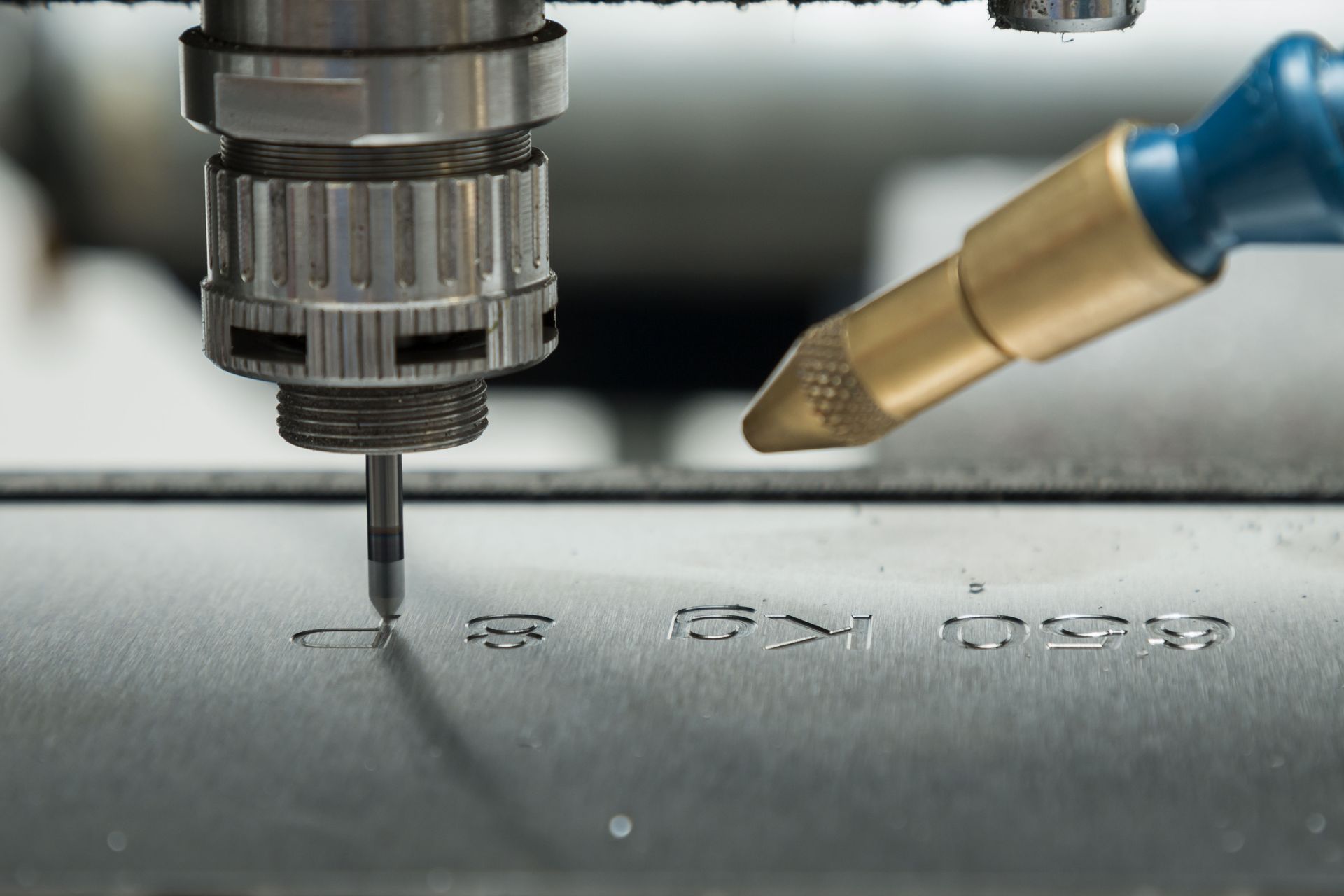

Precision and Accuracy

One of the primary benefits of a CNC machine shop is its unmatched precision. According to Tech Target, modern CNC machinery can maintain tolerances as small as .00004 inches, highlighting the incredible accuracy these systems provide. This precision far exceeds what conventional machines can achieve, making CNC technology indispensable for applications where even minor deviations are unacceptable. By relying on a CNC machine shop, manufacturers can minimize material waste, reduce errors, and ensure that every component meets rigorous standards.

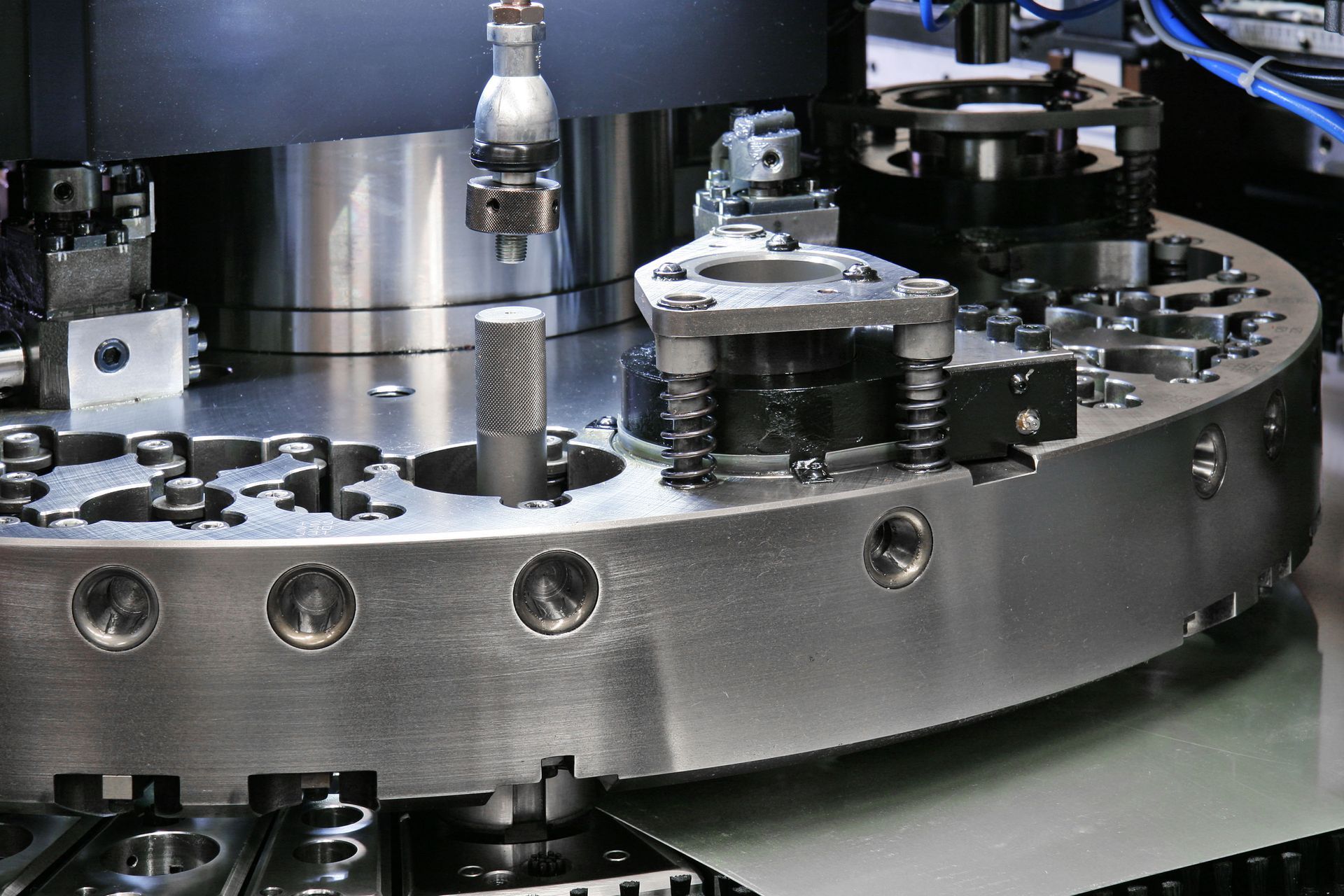

Efficiency and Flexibility

Another key advantage of a CNC machine shop is its efficiency and adaptability. CNC machines operate continuously with minimal human intervention, significantly shortening production cycles. Automated systems allow for seamless transitions between different machining operations, making it easy to accommodate design changes or adjust production for custom projects. This flexibility is particularly valuable for prototyping or small-batch runs, where turnaround time is crucial. By streamlining processes, a CNC machine shop enables manufacturers to maintain high productivity without sacrificing quality.

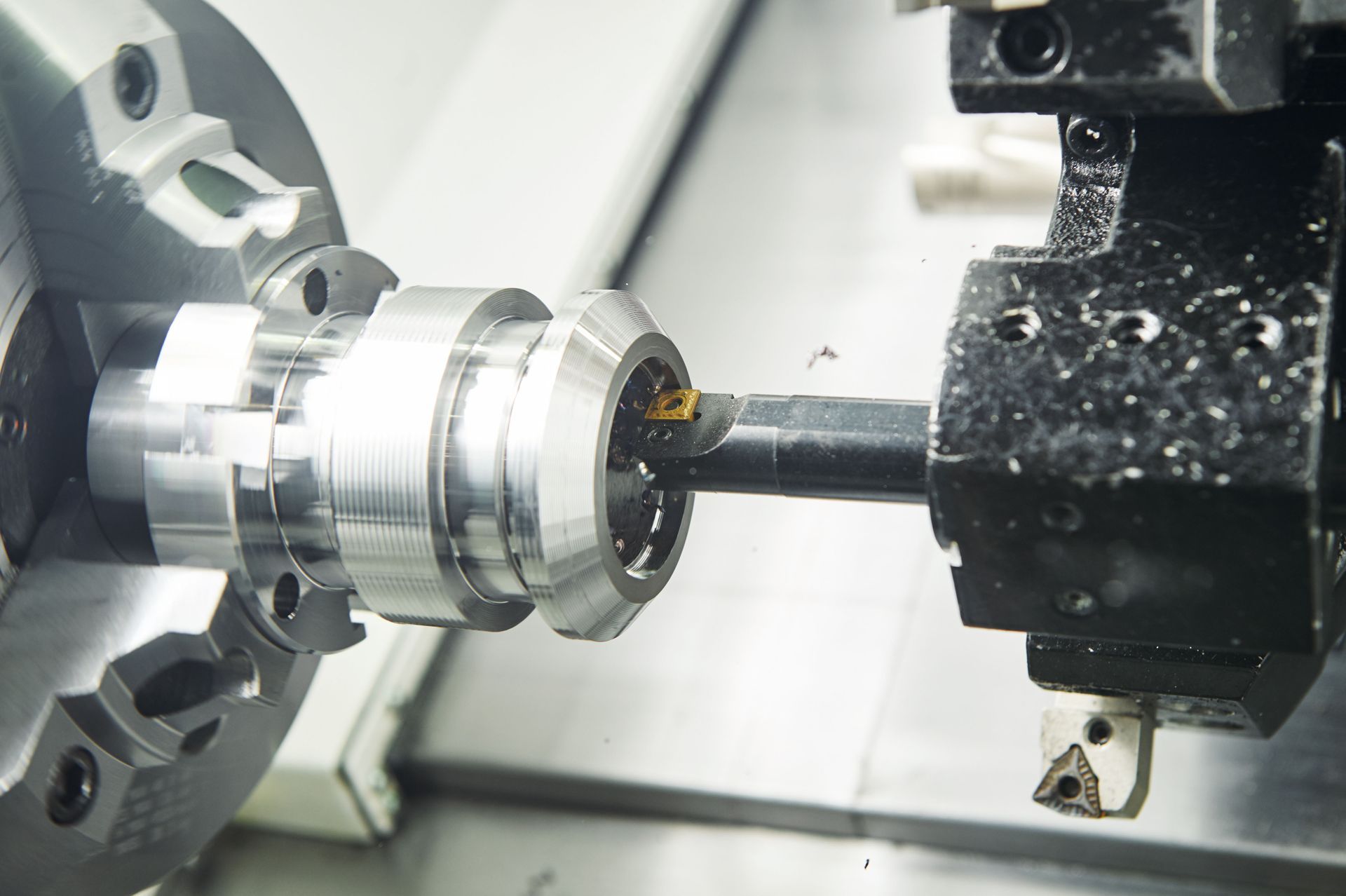

Consistent Quality

Consistency is a hallmark of a professional CNC machine shop. Automated processes reduce the likelihood of human error, ensuring that each part produced matches the last with remarkable uniformity. This consistency enhances product reliability and strengthens customer confidence, especially in industries where performance is critical. Moreover, fewer defects mean less time and cost spent on quality control, allowing resources to be directed toward other important areas of production. The predictable output of a CNC machine shop makes it a trusted solution for both large-scale manufacturing and specialized projects.

Investing in a CNC machine shop delivers clear advantages in precision, efficiency, and consistent quality. From producing intricate components to meeting tight production deadlines, the capabilities of a CNC machine shop help manufacturers maintain a competitive edge. Businesses benefit not only from the accuracy and reliability of CNC technology but also from the expertise of skilled professionals who operate and manage these advanced systems. For manufacturers seeking dependable, high-quality production solutions, partnering with Summit Machine Co, Inc ensures superior results and exceptional service.

Share On: