What Can a CNC Machine Do for You?

In the world of manufacturing and production, efficiency and precision are paramount. A Computer Numerical Control (CNC) machine is a remarkable tool that has revolutionized these industries by offering unparalleled accuracy and productivity. Whether you're an individual hobbyist or a large-scale manufacturer, understanding what a CNC machine can do for you might open doors to efficiencies you hadn't thought possible before. Let's explore the various aspects in which a CNC machine can enhance your operations.

Enhancing Precision and Efficiency Through Automation

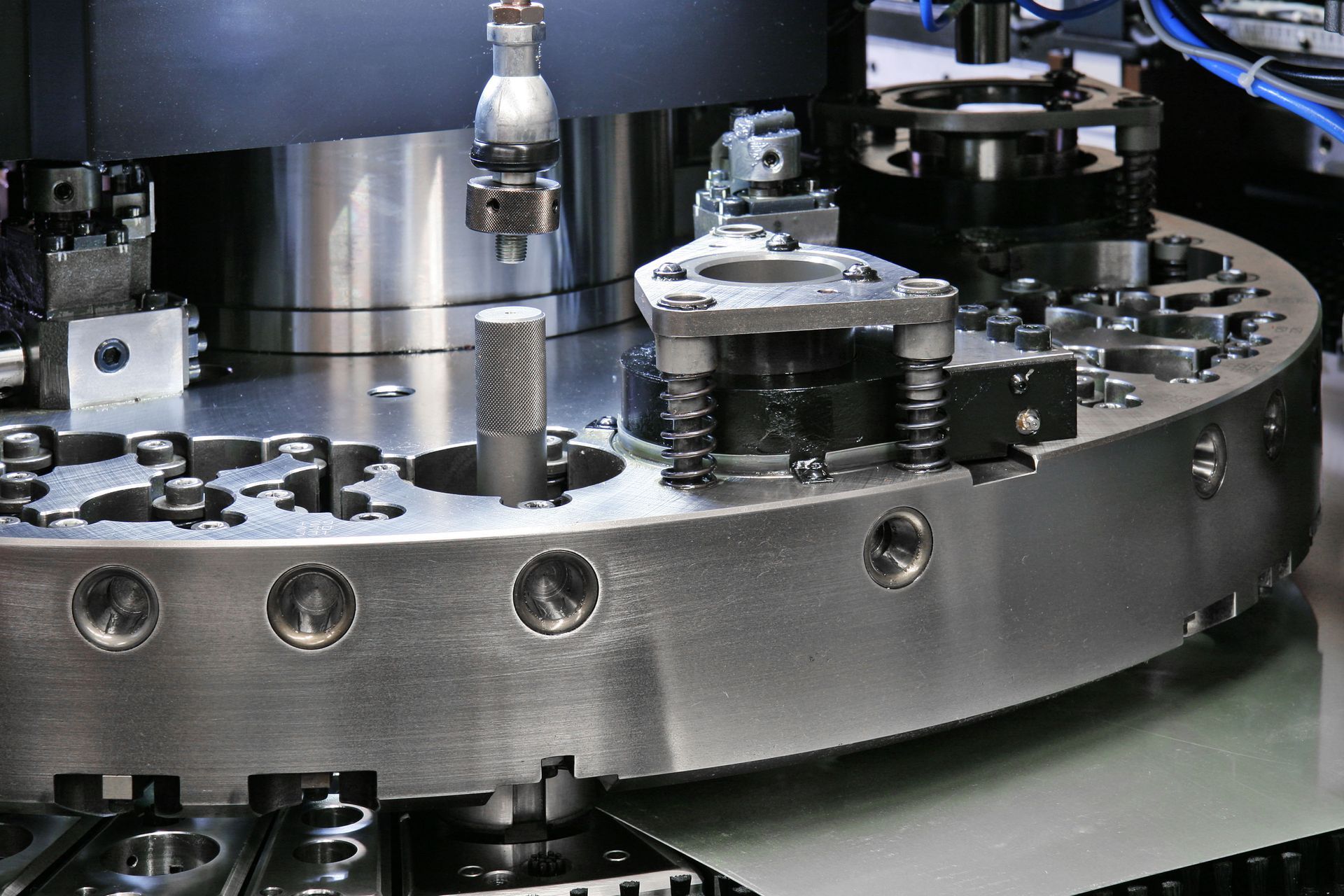

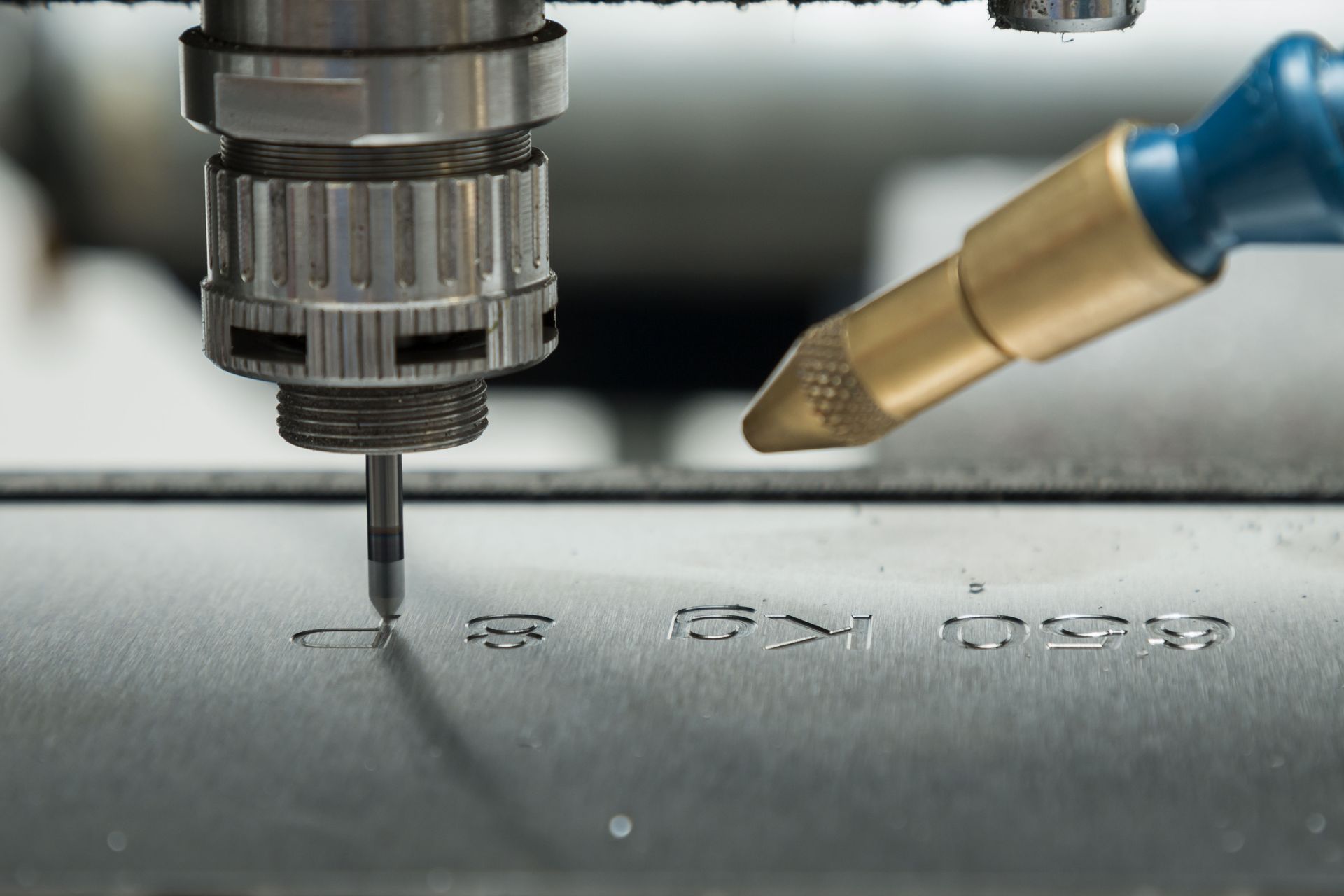

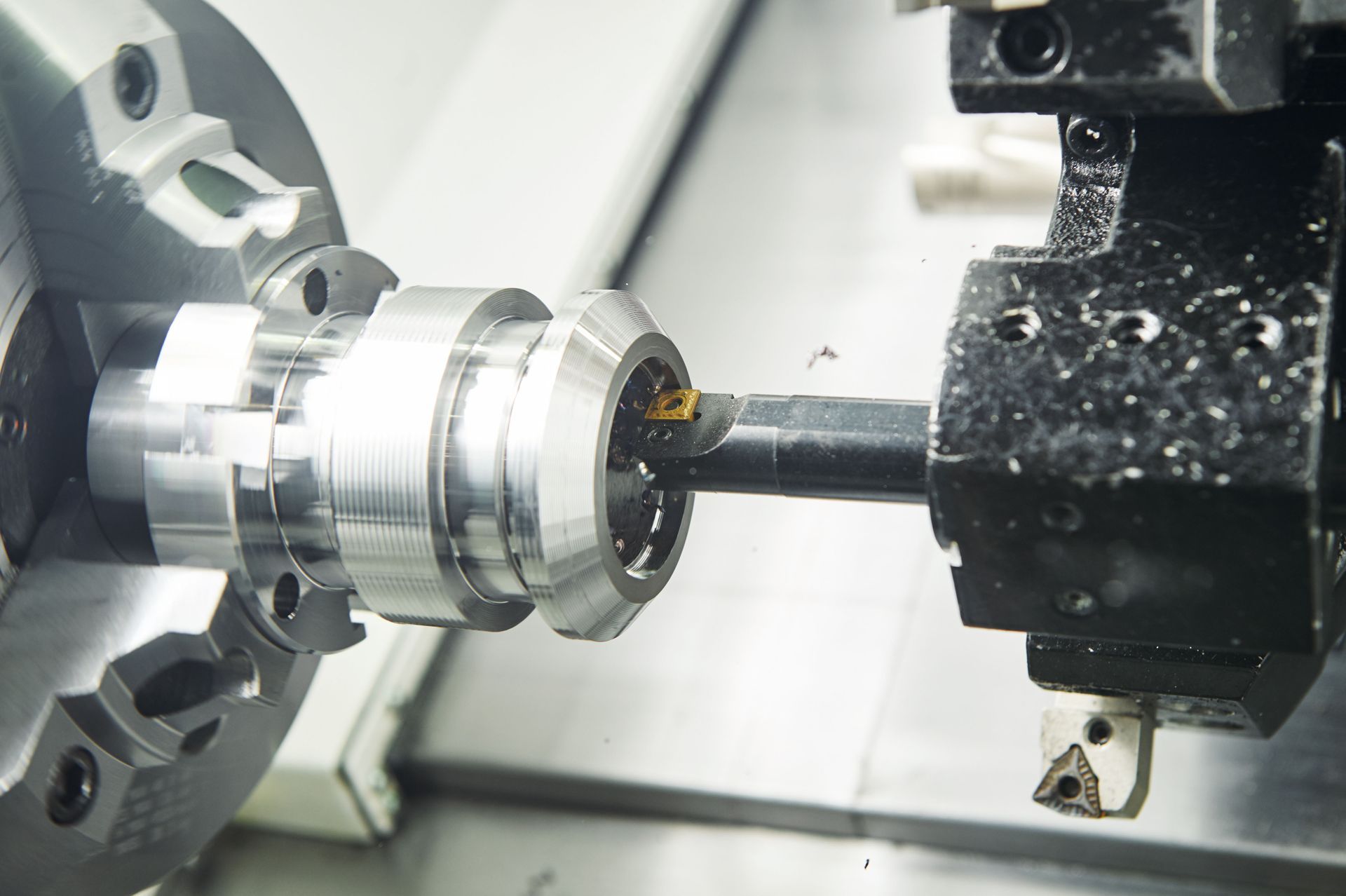

At its core, a CNC machine automates the control of machining tools using a computer. This capability transforms the user's design into reality with incredible accuracy. For businesses, CNC machines are pivotal in increasing the speed of manufacturing processes while maintaining quality. By eliminating the need for human intervention during the machining phase, errors are minimized, which leads to less material waste and higher quality output. This level of precision and efficiency makes CNC machines invaluable in sectors requiring high standards, such as aerospace and medical device manufacturing.

Minimizing Errors and Reducing Material Waste

Interestingly, CNC machines have been around longer than most people realize. According to Tech Target, CNC machines were first patented in 1958. This technology has since evolved from rudimentary machines capable of simple operations to complex systems capable of executing intricate patterns and custom designs. Over the decades, enhancements in software and hardware technology have expanded the capabilities of CNC machines, allowing them to handle a variety of materials, from metals and plastics to wood and ceramics, thereby making them versatile tools in both small-scale craft endeavors and large industrial settings.

Expanding Capabilities Through Technological Evolution

Moreover, CNC machines offer benefits beyond precision and speed; they also enhance safety. Traditional machining can be hazardous, involving sharp tools and materials moving at high speeds. CNC machines, however, reduce risk by automating processes that would otherwise require close human interaction. As a result, workplaces can enjoy a safer environment whilst still achieving exceptional productivity levels. Additionally, the automation of repetitive or dangerous tasks enables human operators to focus on other critical areas of production management.

Whether you're looking to enhance productivity, ensure precision, or improve safety in your manufacturing processes, CNC machines present compelling benefits. These machines, with their rich history and continuous progression, are essential tools in the modern age, transforming designs into tangible products with precision and efficiency that manual methods simply cannot match. Embracing CNC technology can significantly influence your production capabilities, giving you a competitive edge in today's fast-paced market. If you need precise, reliable CNC services, contact Summit Machine Co, Inc today!

Share On: